Product Details

Product Introduction

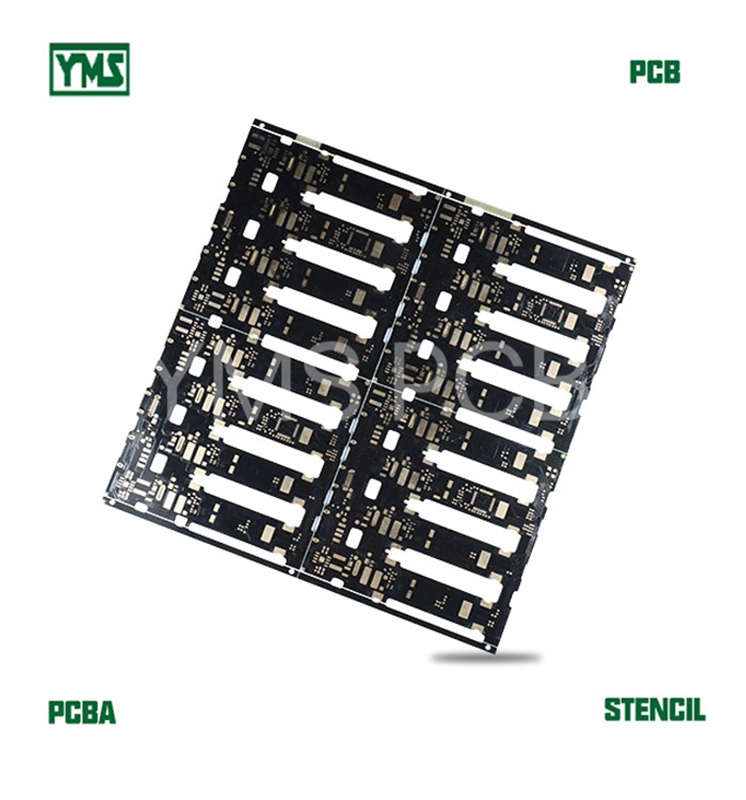

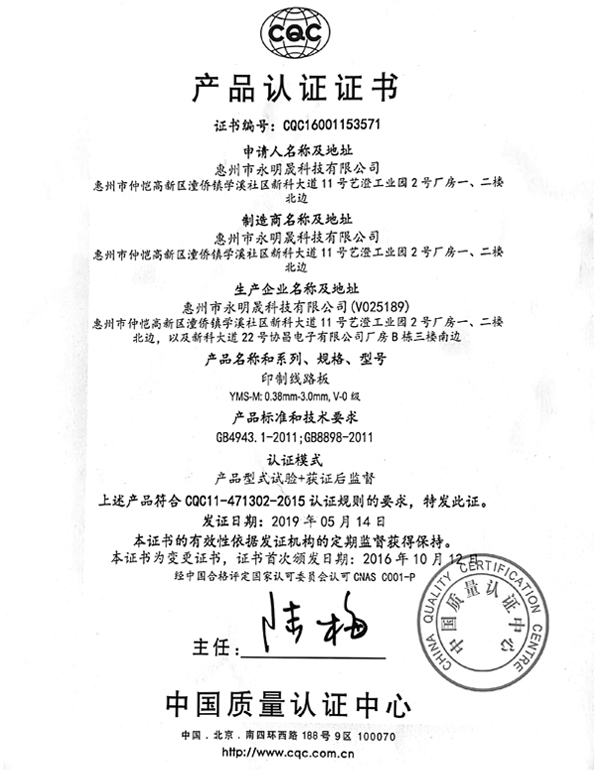

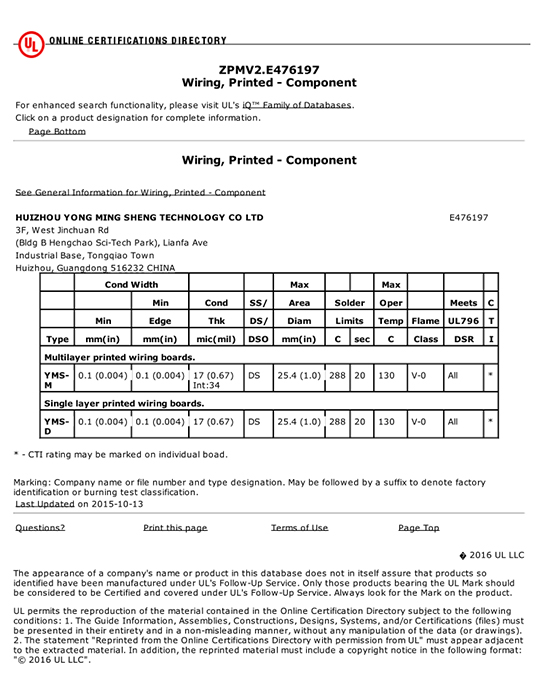

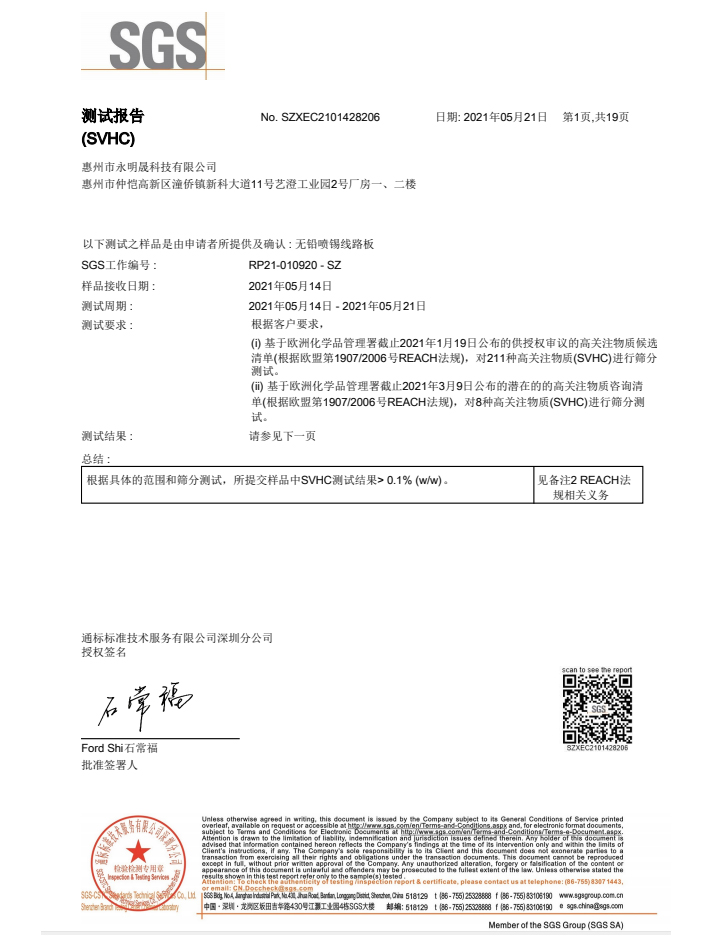

Using the high TG characteristics of IT-180A (ITEQ) material, this 30-layer HDI high-density interconnect circuit board has multiple laser drilling and compression bonding processing technologies. The board thickness is 2.0mm, the outer copper foil thickness is 1OZ, the inner copper foil thickness includes 1OZ and HOZ, the minimum through hole is 0.2mm, the minimum laser aperture can reach 0.1mm, and the minimum line width and line spacing are both 3mil ( 0.075mm), and the surface treatment adopts immersion gold (ENIG) process. This product is used in fields such as mobile phones and telecommunications, and is especially suitable for high-end smartphones that require high precision and tight layout. The product's blind and buried hole technology is widely used in high-end electronic products. The outer layer of visible ink is black and the silk screen is white, and complies with IPC-II standards and impedance requirements. The product not only has excellent electrical performance, but also has passed multiple certifications such as UL, TS16949, ISO9000, etc., ensuring the stability and reliability of product quality.

Advantages and features

- High TG ITEQ IT-180A material ensures long-term stability and heat resistance in high temperature applications. - 30-layer high-density board design supports multiple laser drilling and precision compression bonding processes to meet complex circuit configuration requirements. - Micro through hole technology, achieving a minimum through hole of 0.2mm and a laser aperture of 0.1mm, ensuring the ultimate in stable signal transmission. - Excellent circuit design, the minimum line width and line spacing are 3mil (0.075mm), suitable for high-density electronic component layout. - Immersion gold (ENIG) surface treatment process enhances welding strength and oxidation resistance, extending product life. - Comply with IPC-II standards and precise impedance control requirements to ensure circuit board performance. - Multiple international certifications (including UL, TS16949, ISO9000), emphasizing the high standards and reliability of products.

Application Scenario

- High-end smartphone manufacturing, especially for devices with high requirements for precision and layout, supporting their performance and functional complexity. - Communication equipment, such as base stations, routers, switches and other high-speed signal transmission and processing applications. - The field of mobile communications, including 4G/5G network equipment, meets its needs for high-frequency and high-speed data transmission. - Internet of Things (IoT) devices, smart home and wearable devices that require compact PCB space and high signal integrity. - High-precision electronic computing and storage equipment, such as servers, high-performance computers, etc., which require high-reliability circuit boards to carry high-speed data processing tasks. - Automation and control systems. In industrial and automotive applications, these systems need to bear a large amount of data interaction and require precision and high-reliability circuit boards as core components.