Product Details

Product Introduction

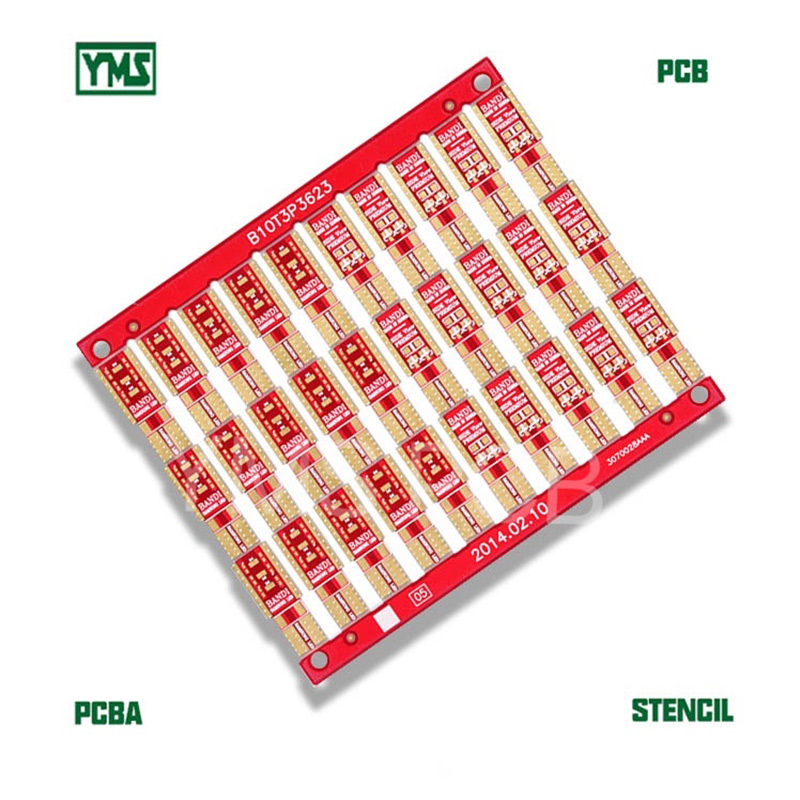

Mingzhenghong Electronics Co., Ltd. specializes in providing high-frequency PCB boards for Huawei/ZTE 5G base stations. The products use ROGERS materials such as RO4003, 4350, 5880, etc., as well as other brand materials such as POLYIMIDE, TACONIC, PANASONIC, etc., to meet the needs of different customers and application fields. need. The PCB board is designed as a 6-layer structure, using a combination of ROGERS 4003 and FR-4 TG170 (IT-180A) materials. ROGERS 4003 is used for L1-L2/L5-L6 in the stack, and FR-4 TG170 is used for other layers to ensure the protection of high-frequency signals. Integrity and stability. The outer copper foil and inner copper foil are both 35 microns, the minimum drilling diameter is 0.25mm, and the minimum line width/line spacing reaches 4mil (0.1mm). The board thickness is 1.6mm, the PCB is 200mm long and 105mm wide, with an aperture ratio of 6.4:1. The surface treatment adopts the immersion gold process (ENIG), and the thickness of the gold layer is 3u". The product complies with the 94V0 RoHS standard, has passed CE, RoHS, UL, SGS, ISO9001 and other certifications, supports impedance control requirements, and is equipped with red solder resist paint and white Silk screen. Mingzhenghong Electronics Co., Ltd. uses advanced LDI equipment to provide customers with more than 500,000 5G base station PCB boards annually, ensuring high quality and precision.

Advantages and features

- Using advanced ROGERS and thermosetting high TG FR-4 material combination to achieve excellent high-frequency performance and ensure the stability and integrity of signal transmission; - Multi-layer PCB design, 6-layer stack structure, strengthen the signal level and integrity of the circuit board Overall mechanical strength; - Precision processing capability, which can reach a minimum line width/space of 4mil and a minimum drilling diameter of 0.25mm to meet high-density wiring requirements; - Surface immersion gold technology (ENIG) application, providing 3u" gold layer Thickness, giving good welding performance and long-term oxidation resistance; - Comply with 94V0 RoHS standard, and passed multiple international certifications such as CE, RoHS, UL, SGS, ISO9001, etc. to ensure the environmental protection and safety of the product; - High-precision LDI Equipment production line to ensure quality consistency and high precision in mass production.

Application Scenario

- 5G base station PCB board specially designed for large communication equipment manufacturers such as Huawei/ZTE, suitable for building high-performance 5G communication infrastructure; - Can be widely used in high-speed data transmission fields, such as data centers, network access equipment, wireless routers and switches; - Suitable for any electronic equipment that needs to ensure high-frequency signal transmission quality, including aerospace, military communications, medical equipment and other precision instruments; - For application scenarios that require high temperature stability and good electromagnetic compatibility, provide reliable PCB solutions; - Suitable for complex electronic systems that require precise impedance control to ensure system performance and complete signal transmission.