Product Details

Product Introduction

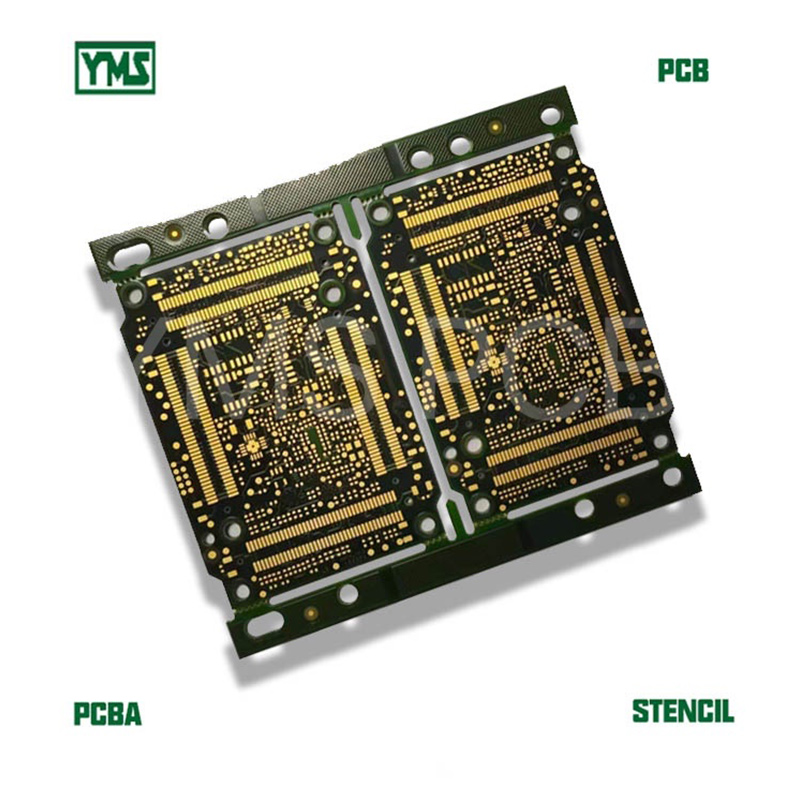

The 8-layer high-density interconnect (HDI) rigid-flex board is an innovative circuit solution produced by Mingzhenghong Electronics Co., Ltd. with exquisite craftsmanship. This product uses FR-4 (ITEQ) and PI (polyimide) as the base material, which has both rigid and flexible characteristics. The size is 143.2 , the copper thickness of the inner and outer layers is 35 microns. Its minimum aperture reaches 0.125 mm, the minimum line width in the rigid area is 4mil, and the flexible area is 3mil; the line spacing also has high precision requirements, the rigid area is 3mil, and the flexible board area is 2mil. The surface of the product has been treated with the ENIG process and plated with a 3-micron thick gold layer to improve conductivity and corrosion resistance. The product has obvious features, integrating the complexity of multi-layer boards and the diversity of flexible circuit boards, and interconnecting through internal and external plated through holes. The green solder mask is used to cover the rigid area, and the yellow covering layer is used to cover the flexible board area. The appearance is neat and provides an excellent and reliable circuit platform for applications such as camera modules, medical instruments, and lighting systems. This product combines high-density wiring, multi-functionality and excellent durability, and is specifically designed to meet the needs of advanced electronic devices such as mobile communications and precision medical equipment.

Advantages and features

- Innovative combination: Combining the stability of rigid PCB and the flexibility of flexible FPC to achieve the compact and complex layout requirements of advanced electronic equipment. - High-density interconnection: HDI technology is used to achieve smaller aperture (0.125mm) and high-precision line width/line spacing (rigid area 4/3mil, flexible area 3/2mil), suitable for high-density wiring of complex electronic systems . - Strong durability: The 3-micron gold layer provided by the ENIG process enhances conductivity and corrosion resistance, ensuring long-term reliability. - Environmentally friendly materials: FR-4 and PI base materials meet environmental requirements and adapt to the market trend of sustainable development. - Exquisite appearance: The green solder mask and yellow covering layer are beautiful and functional, enhancing the product experience and durability.

Application Scenario

- Mobile communications: Provide complex and reliable circuit solutions for mobile products such as smartphones and wearable devices. - Precision medical equipment: Compatible with the requirements for high precision and stability of medical equipment, such as portable medical monitoring equipment, imaging equipment, etc. - Industrial automation: Suitable for automation control systems that require redundant design and efficient machine operation. - High-end camera module: Supports high-definition acquisition of camera modules, improving the performance and stability of the imaging system. - Lighting system: suitable for intelligent lighting control systems, especially designs that require curved installation or compact space.