In recent years, multilayer printed circuit boards (PCBs) have emerged as a cornerstone technology in the field of smart manufacturing. These sophisticated devices enable unprecedented levels of integration and functionality in modern electronics. As industries transition towards Industry 4.0, the innovative capabilities of multilayer PCBs are paving the way for enhanced efficiency, reliability, and performance.

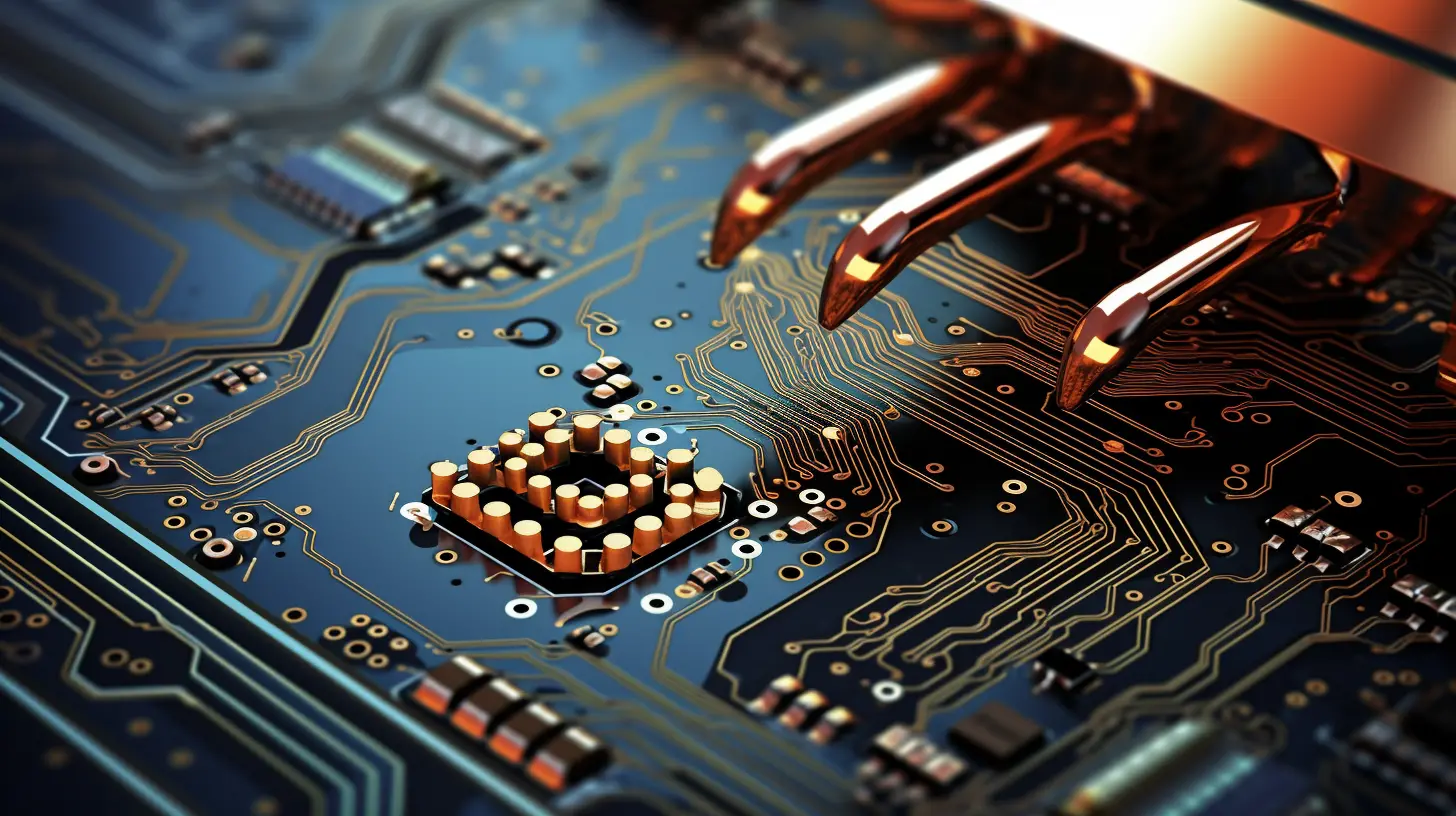

The primary advantage of multilayer PCBs lies in their ability to accommodate complex circuitry in a compact form factor. By stacking layers of conductive pathways and dielectric materials, these PCBs facilitate higher component density, reducing the size of electronic assemblies without compromising performance. This capability is vital for smart manufacturing systems that demand compact and efficient designs.

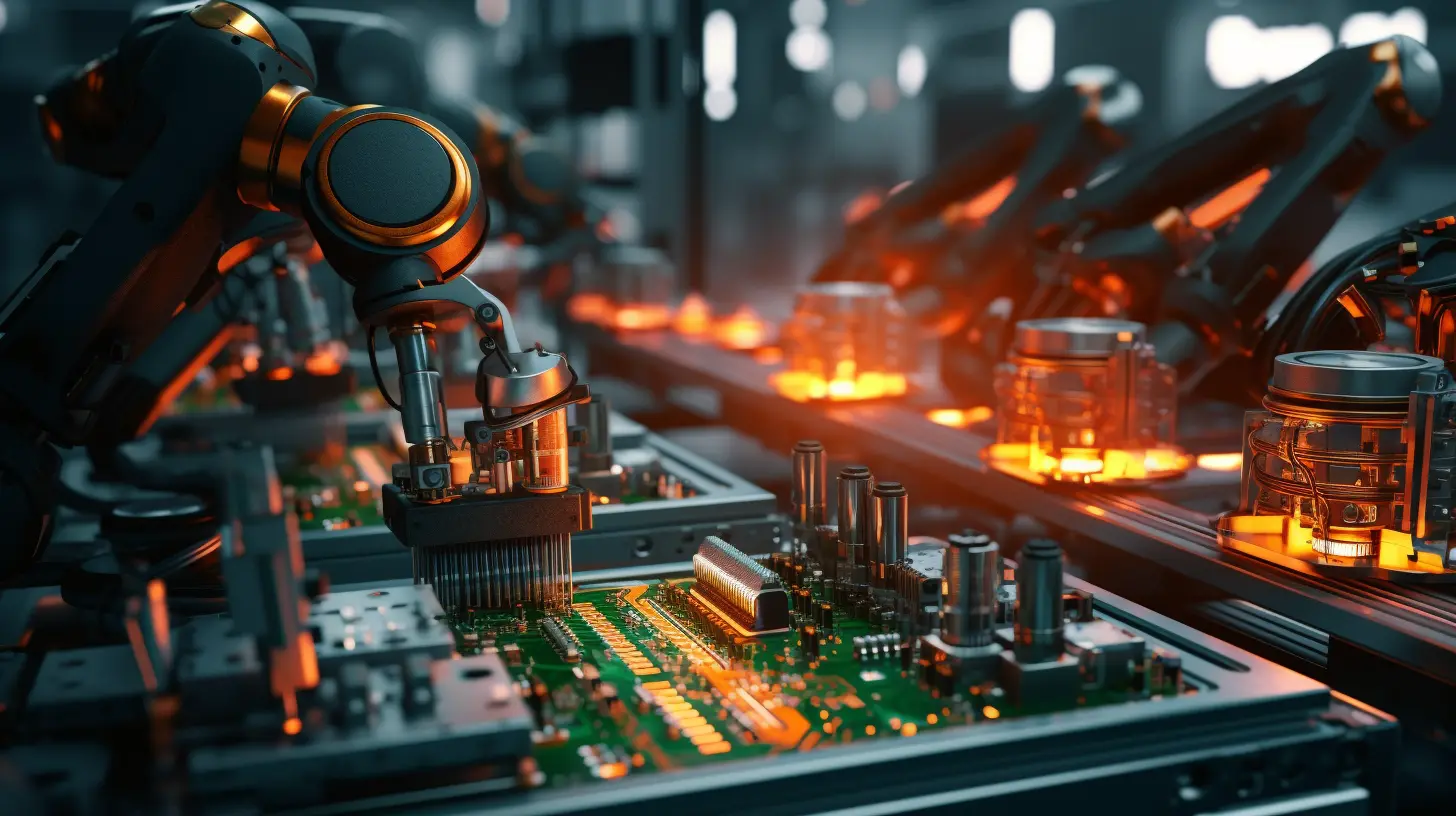

Multilayer PCBs play a crucial role in several applications within smart manufacturing, including automation systems, robotics, and IoT devices. Their ability to enable high-speed data transmission and power distribution is essential for ensuring seamless communication between devices. Additionally, the integration of sensors and control systems on a single PCB can significantly streamline manufacturing processes, resulting in increased productivity and reduced operational costs.

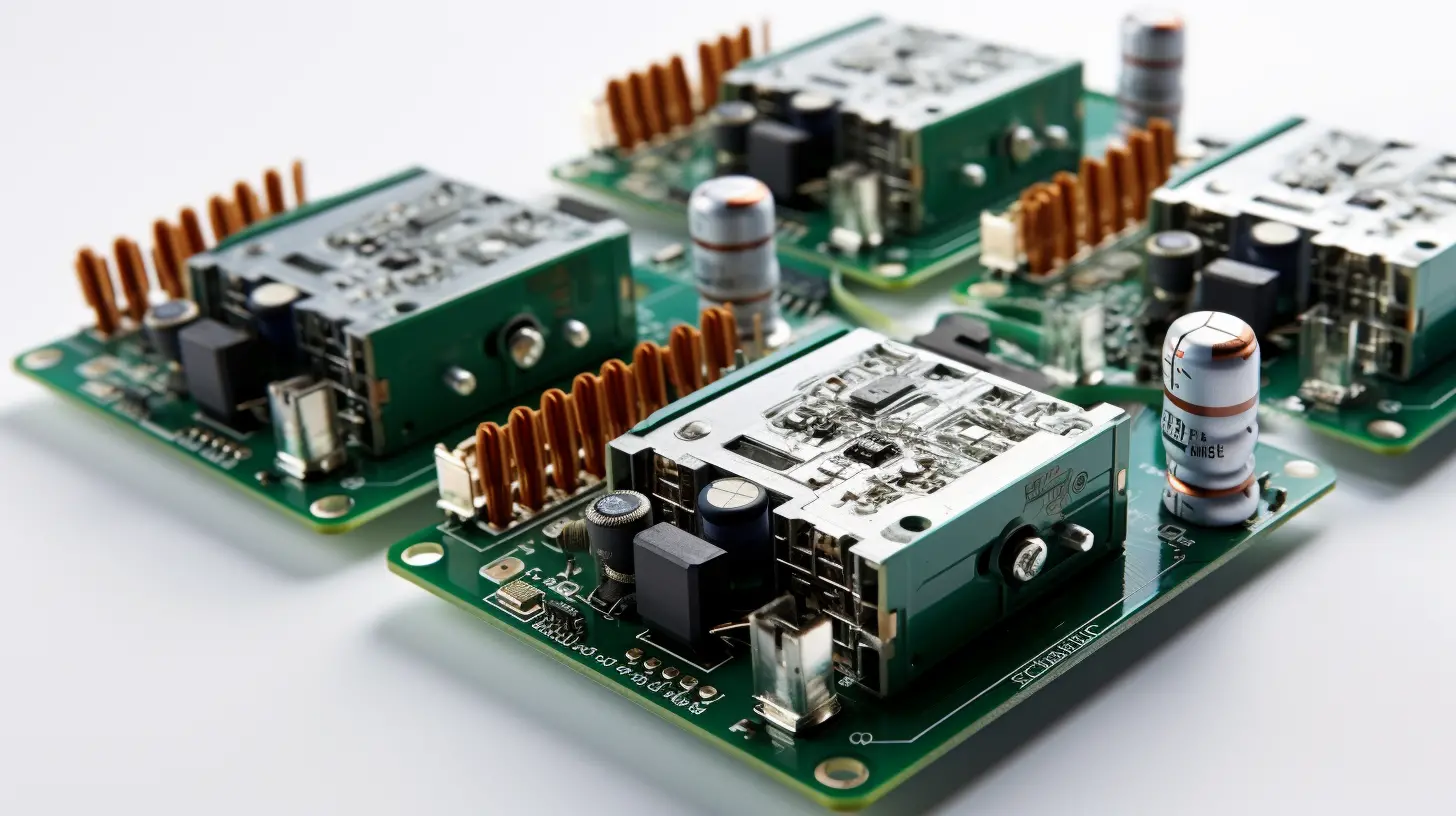

As the demand for smarter, more efficient manufacturing solutions continues to grow, multilayer PCBs are set to become an integral component of the electronics industry. Their innovative applications not only enhance productivity but also support the ongoing evolution towards fully automated systems. Embracing these technologies will empower manufacturers to stay competitive in an ever-changing market landscape.