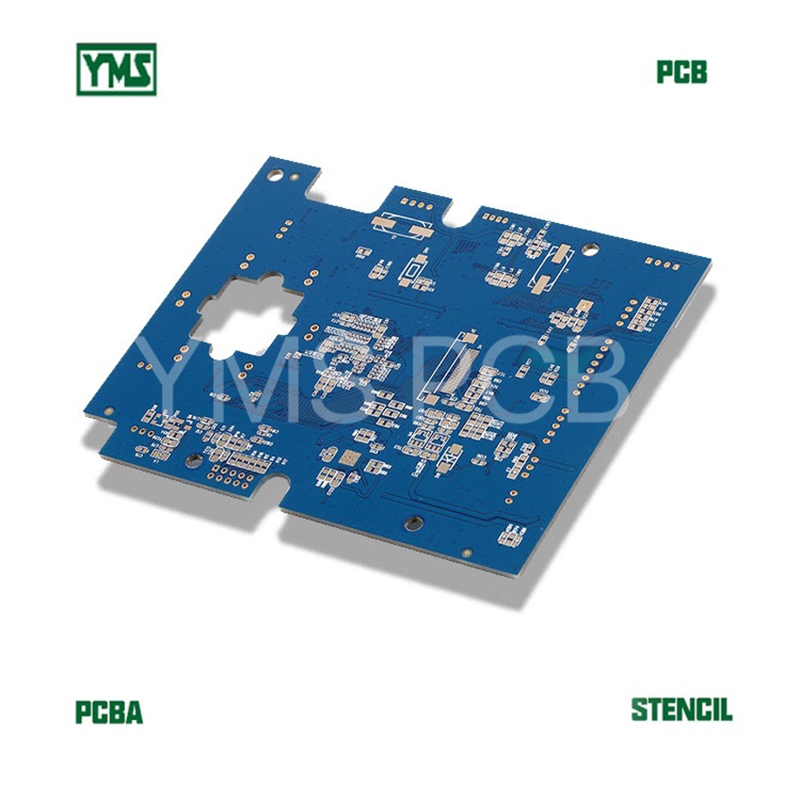

High-Performance Hybrid Rigid-Flex PCB - 8-Layer Hard-Flex Composite Plate

06 02,2025

Mingzhenghong Electronics Co., Ltd.

Share and exchange

Discover our innovative 8-layer hard-flex composite plate featuring superior mechanical strength and electrical performance. Designed for high-frequency applications, our high-performance hybrid rigid-flex PCB incorporates advanced laser drilling and VIA in pad processes. Compliant with RoHS and REACH standards, this solution meets the rigorous demands of high-end markets including communication, medical, and industrial automation.

Introduction

In today's fast-paced technological landscape, the demand for high-performance PCB solutions continues to grow, particularly in industries that require reliability and precision. Our 8-layer hard-flex composite plate represents the forefront of innovation in hybrid rigid-flex PCB technology, expertly integrating advanced manufacturing processes to meet the most stringent requirements of modern applications.

Challenges in PCB Design

High-density interconnect (HDI) applications pose unique challenges in PCB design, including the need for mechanical strength, flexibility, and precise signal integrity management. Traditional rigid PCBs often lack the flexibility necessary to fit in compact spaces while still providing robust performance and reliability. This can lead to issues in signal degradation and component reliability in high-frequency environments.

Our Solution: The 8-Layer Hybrid Rigid-Flex PCB

We have developed a cutting-edge hybrid rigid-flex PCB that combines the best of both hard and soft materials. Our 8-layer structure consists of six rigid layers and two flexible layers, delivering exceptional mechanical strength and electrical performance.

Key Features:

- Advanced Laser Drilling: Utilizing MITSUBISHI laser drilling technology, we achieve unparalleled accuracy in L1-L3 and L6-L8 dual-step laser hole processing.

- VIA in Pad Technology: Our implementation of blind buried vias allows for high-density interconnections while maintaining a compact design.

- ENIG Surface Finish: This chemical gold plating ensures excellent solderability and long-term reliability, suitable for the most demanding electronic applications.

- Impedance Control: Tailored layer stacking ensures precise impedance control, safeguarding signal integrity for high-frequency data transmission.

- BGA Resin Fill: The application of BGA resin filling supports small-pitch BGA packaging, enhancing assembly density and reliability.

- Environmental Compliance: Our PCBs comply with RoHS and REACH environmental standards, aligning with the global push for eco-friendly electronics manufacturing.

Applications

The versatility of our 8-layer hybrid rigid-flex PCB makes it applicable across various high-end sectors:

- Telecommunication Equipment: Ideal for complex signal transmission tasks in devices such as base stations, routers, and switches.

- Medical Instruments: Critical circuit board applications, ensuring device precision and stable electronic performance.

- Industrial Automation: Suitable for electronics in harsh environment applications, such as control systems and sensor interfaces.

- Consumer Electronics: Perfect for high-density packaging and complex circuit designs used in smartphones and wearable devices.

- Energy and Automotive Electronics: Provides reliable circuit solutions to meet strict performance requirements in new energy vehicles and automotive applications.

Conclusion

Our high-performance hybrid rigid-flex PCB is engineered to meet the evolving needs of modern electronics, delivering superior performance in compact, high-density designs. As industries continue to innovate and demand higher specifications, our commitment to quality and advanced technology positions us as a leader in PCB solutions, paving the way for the future of electronic manufacturing.