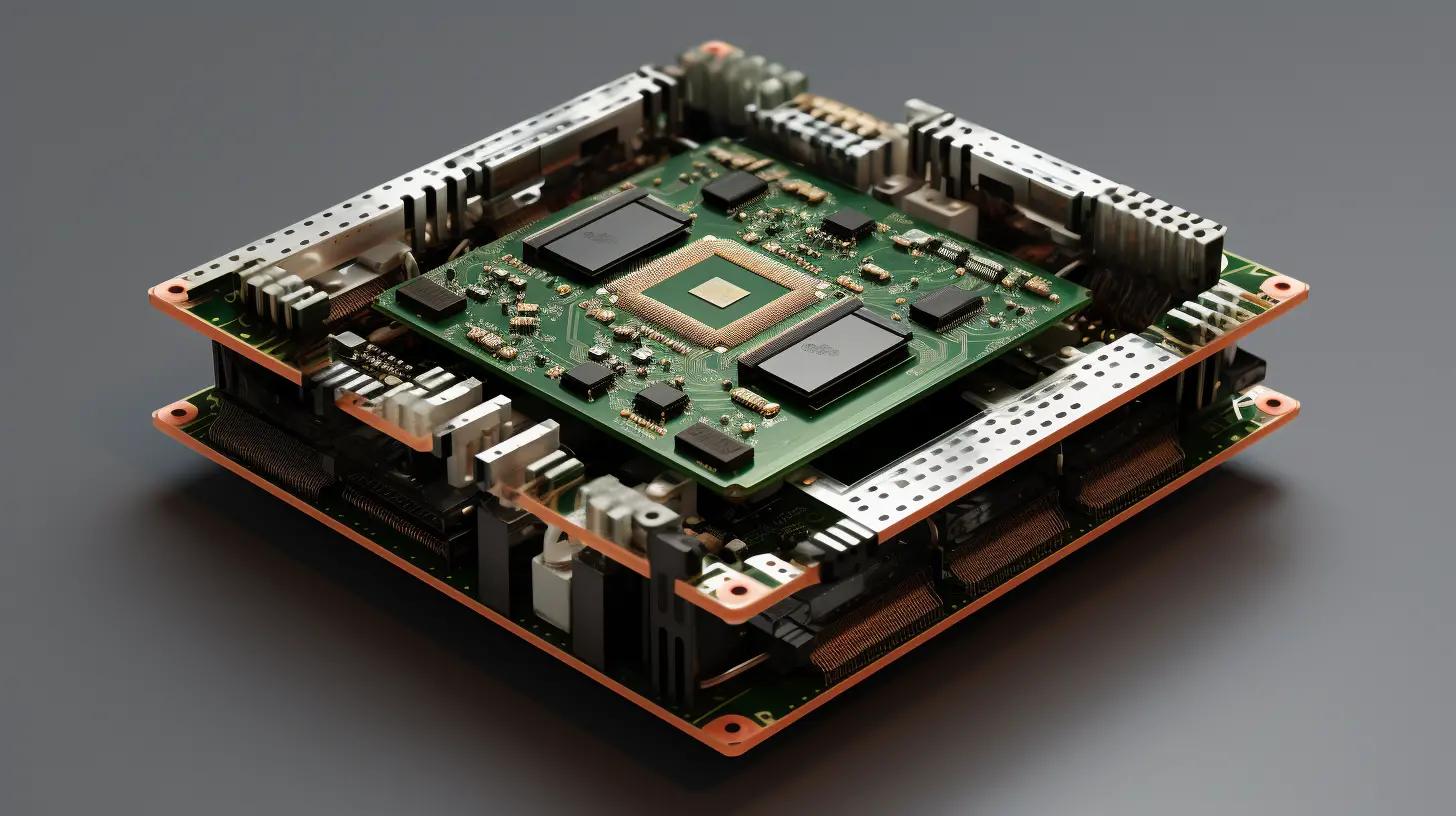

In today's advanced electronics landscape, high-temperature stability in printed circuit boards (PCBs) is essential. PCBs are used in a variety of demanding applications, from automotive to aerospace. These environments often subject PCBs to extreme temperature fluctuations, making their thermal stability a critical factor for reliability and longevity.

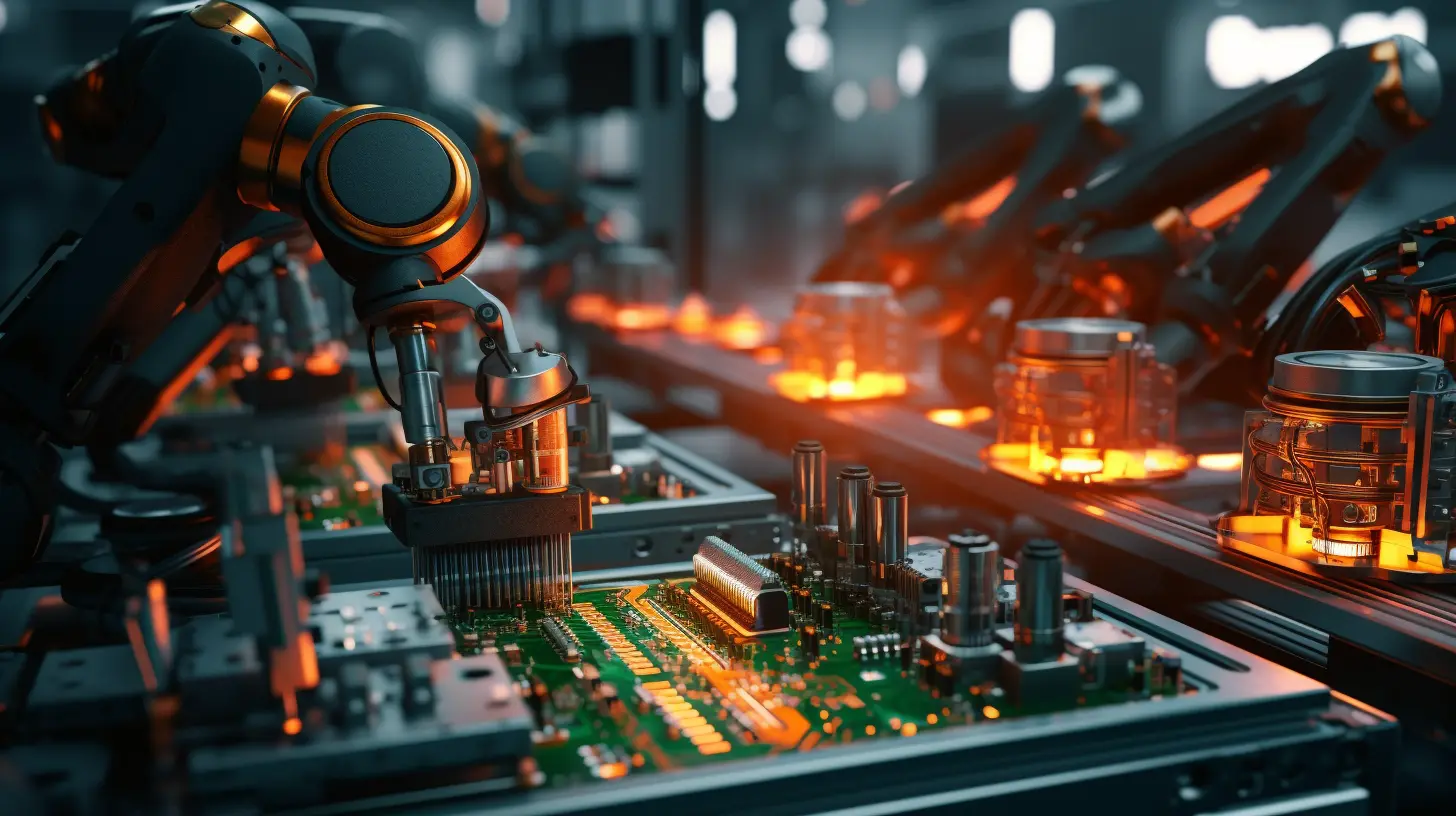

To achieve high-temperature stability, manufacturers utilize advanced materials that enhance thermal resistance. These materials help in minimizing thermal expansion and ensuring that circuit functions remain intact under high heat conditions. It is important to evaluate the thermal properties of copper, dielectrics, and substrate materials when designing PCBs for high-temperature applications.

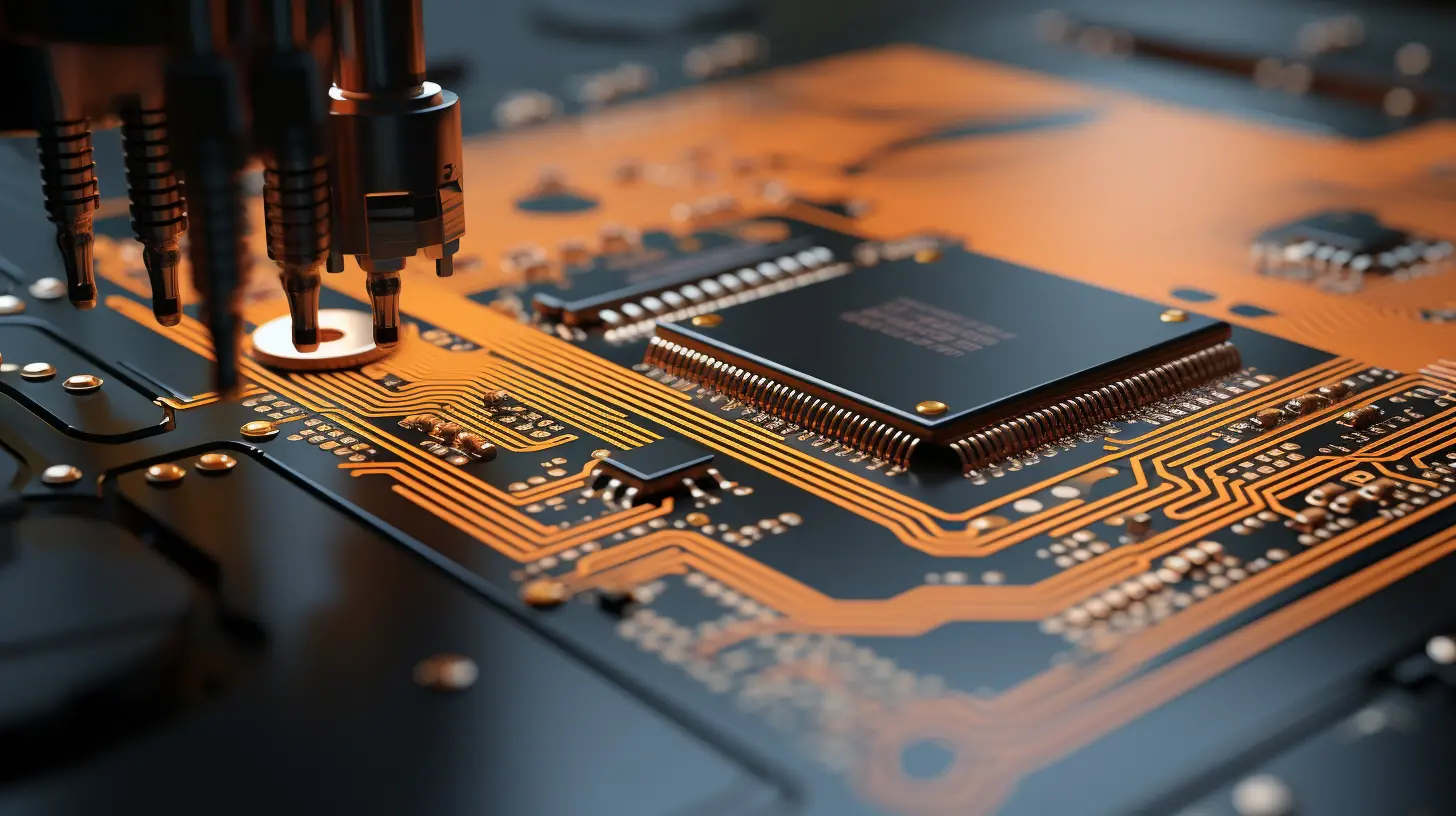

Recent studies show that PCBs designed specifically for high-temperature applications can operate effectively at temperatures exceeding 200°C. This capability not only improves the reliability of electronic devices but also extends their lifespan, leading to lower maintenance costs for manufacturers and end-users alike.

In conclusion, exploring high-temperature stability in PCBs is critical for ensuring the performance of advanced electronic applications. By focusing on the right materials and technologies, manufacturers can create reliable and robust PCBs capable of withstanding the rigors of high-temperature environments.