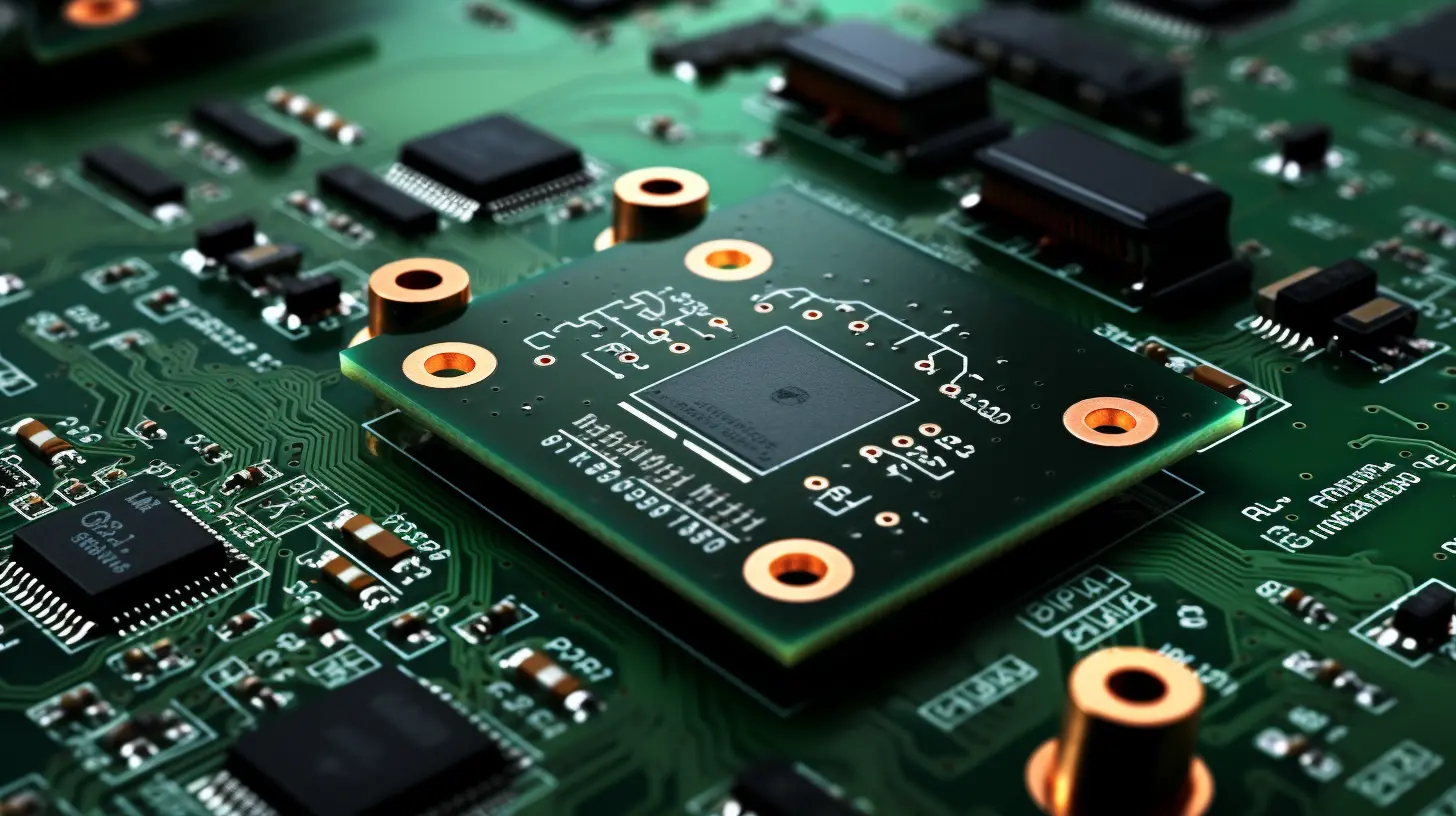

ENEPIG (nickel-gold-nickel-silver) is an advanced surface treatment technology that is widely used in the manufacturing of automotive electronic PCB boards. It can effectively improve the welding performance and oxidation resistance of circuit boards, making it an ideal choice for future electronic manufacturing.

PCB boards using ENEPIG technology can maintain excellent conductive properties in high temperature and humid environments. This is particularly important for the stability of automotive electronic systems, reducing failures and ensuring driving safety.

This technology significantly extends the service life of the product by optimizing the surface structure. Data shows that the robustness has increased to more than 95%, ensuring the long-term stable operation of the product.

With the rapid development of automotive electronics, traditional materials and processes are difficult to meet increasingly stringent performance requirements. The advantages demonstrated by ENEPIG make it stand out in the new round of technological changes.

ENEPIG surface treatment technology provides not only a technological breakthrough for automotive electronic PCB boards, but also a new way of thinking for future manufacturing. For automobile manufacturers, choosing ENEPIG products means choosing a safe and reliable future.

Want to know more technical information about ENEPIG? Please interact with us and share your views!