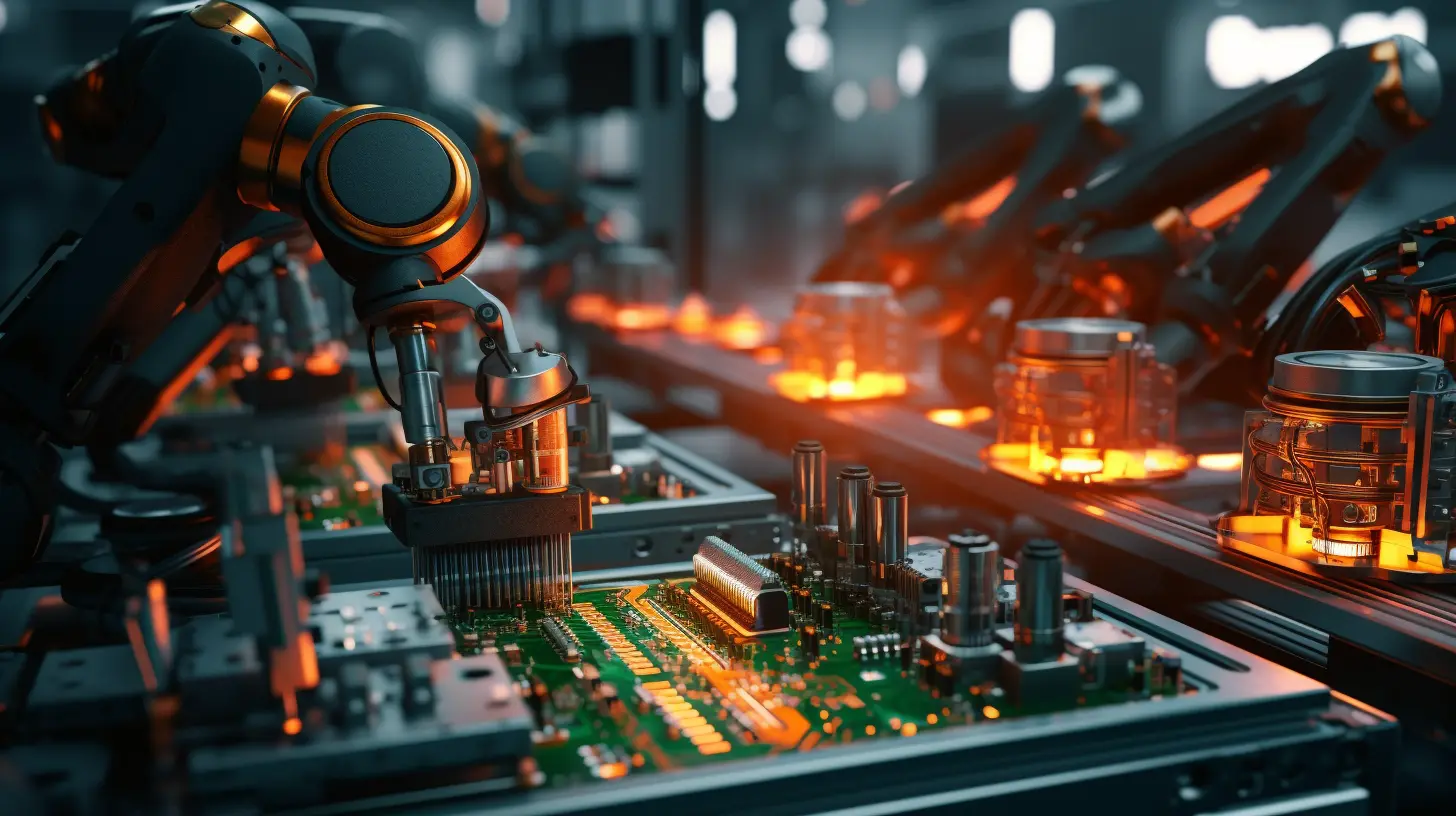

In the rapidly evolving world of electronics, the demand for high-performance printed circuit boards (PCBs) has surged. Traditional PCB manufacturing methods face challenges in achieving higher density, reliability, and cost-effectiveness. Thus, advanced laser drilling technology emerges as a vital solution.

Conventional methods of PCB drilling such as mechanical drilling are often limited by factors like pad damage, hole misalignment, and reduced overall precision. As components on PCBs get smaller, the need for microvias and higher layer counts becomes critical. These requirements strain traditional methods, leading to increased production costs and longer lead times.

Advanced laser drilling technology offers a remedy to these challenges. By utilizing precision laser techniques, manufacturers can efficiently create microvias and accurate holes with minimal thermal impact on the surrounding materials.

The key benefits of laser drilling include:

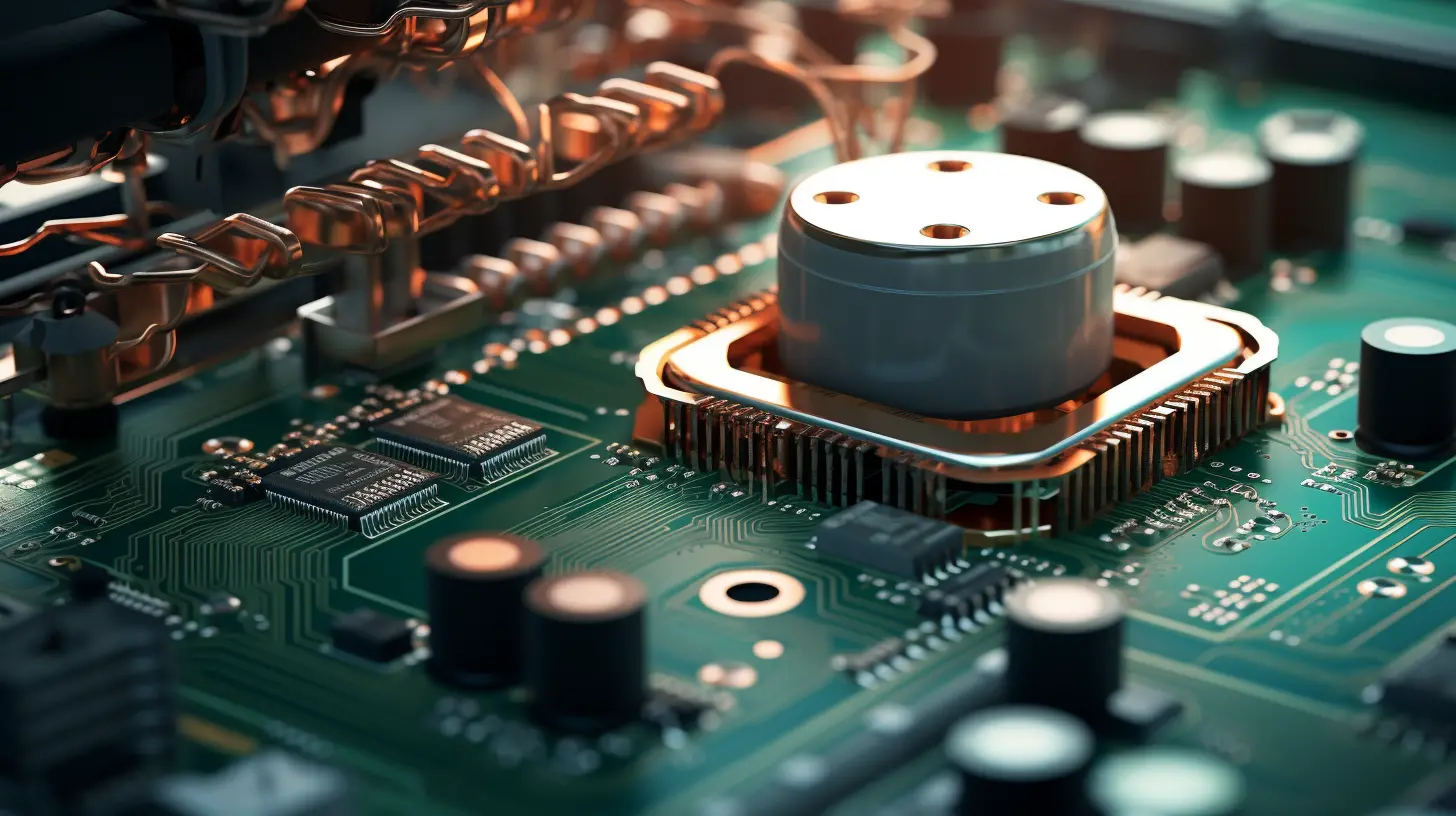

Adopting laser drilling technology not only streamlines the manufacturing process, but also enhances the overall performance of the PCB. The ability to produce tightly packed circuits with high integrity leads to better signal transmission and lower electromagnetic interference.

In conclusion, advanced laser drilling is paving the way for a new era in PCB manufacturing. As industries demand higher performance and more complex designs, laser drilling technology stands out as the key to meeting these evolving needs.

With its numerous advantages and proven effectiveness, laser drilling technology is undoubtedly the future of PCB manufacturing.